How Romotive Went from Prototype to Polished Product

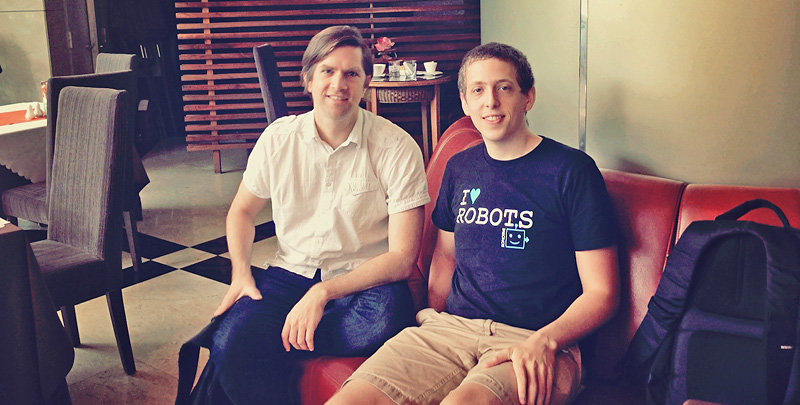

This morning I met up in Shenzhen with Peter Seid, one of the cofounders of Romotive. I first met Peter and his co-founder Phu in Seattle at a TechStars mentor-startup mixer just days after they were accepted into the program. Back then, they had a crude, hand-soldiered robot prototype consisting of a circuit board and some motors and which used an iPhone as the brain. To keep things simple, the iPhone talked to the robot using the audio jack (high pitch tone for moving forwards and low-pitched tone to move backwards.) It was easy to see how this combination of relatively inexpensive hardware plus the connectivity and power of a smart phone could lead to interesting things. It was the first time I’d seen that pattern in practice.

But the guys had basically no real-world experience, and back then, anything with “hardware” in it felt somehow doomed. Who the heck would be crazy enough to start a hardware company, let alone to invest in one? To be quite candid, the back-channel chatter among mentors wasn’t very enthusiastic (to say the least.) “Most of the mentors told us to pivot,” Peter told me, “but we stayed the course.” They’ve come a long way. Now, just a couple of years later, Romotive has two successful kickstarters under their belt, have been featured on the Today Show and are shipping a polished product. And they’ve raised more VC dollars than any other startup from their TechStars batch. Not bad!

Peter and I talked about their early days and how they navigated from a prototype to a shipping product, and lessons they learned about crowd-funding and factory production along the way.

Peter and Phu launched their first Kickstarter during the TechStars program for the generation one of Romo. “We didn’t understand manufacturing, but we knew we didn’t want to get locked into a design either, so we were happy to stick to a laser-cut design and to hand-assemble everything ourselves.” They figured out what their costs would be by hunting around on Pololu.com and Sparkfun. In some cases, like for the battery, they contacted the factories directly to negotiate bulk discounts, and they sourced printed circuit boards from China, but assembled them in the USA. “That was a good move because it allowed us to quickly get fixes done since the company was local”, Peter said. Their Kickstarter hit its target of $32,000 in just three days and went on to raise a total of $115,000. They hand-assembled and shipped the first 1500 Romos by hand from their 3-bedroom apartment.

After the success of their first Kickstarter, they began looking for a factory to mass produce the next design iteration of Romo. They turned to consultants who took them on factory tours and helped them understand the basics of manufacturing. They eventually settled on Dragon Innovation (we blogged about them yesterday), who helped them source the same factory that iRobot uses to produce millions of Roombas, an obvious fit for any robot company. Dragon helped with the RFQ process and supplemented Romotive’s growing team with in-house mechanical and electrical engineering design services. Romotive is still working with Dragon Innovation today and Peter seemed pleased with the support and cover they provide. The other consultant he used missed the mark completely, showing them shoddy factories that produced commodity gear like USB cables.

Peter says that when they started Romotive he never thought he would one day be living in Shenzhen. He has been here for 7 weeks and plans to stay for a few more. I asked him why, if they’ve hired Dragon Innovation who has assigned a full-time manager to visit their factory every day, do they feel the need to be in China? It’s complicated, but it boils down the dilemma inherent to any kind of outsourcing: you can’t outsource your core. When it comes to physical products, it’s impossible to completely rely on any outside party for approving subtle but important design details like fit and finish, product feel and features that require a cultural foundation to get right. Going through an intermediary means fewer iterations since communications happen across timezones and shipping samples overseas is measured in days. In short, you can’t outsource your Steve Jobs role.