Innovate with China

We’re changing “Made in China” to “Innovate with China” on our labels, what do you think?

-Eric Pan of Seeed Studio on our visit Sunday

Eric Pan and his company, Seeed Studio, are showing the future of hardware development: hackers around the world innovating on open prototyping platforms, raising funds through crowdfunding platforms like Kickstarter and partnering with Chinese studios to create manufacturable designs in small batches using technology like 3D printing and open source hardware components.

We headed to Shenzhen on Sunday to meet Eric and see Seeed Studio first hand. They are on the forefront of the open hardware movement (or indie hardware, artisanal hardware or whatever you might want to call it.) From their humble beginnings hacking things in a shared apartment in 2008, Eric has grown Seeed Studio into a company of over 100 people and built a platform for the advancement of open hardware development.

Prototyping environments like Arduino which reduce the difficulty of hardware development, supported by the availability of low-cost sensors and wireless modules are spurring innovation and enabling software folks to innovate in hardware. You no longer need an electrical engineering degree, sizable budget and large time commitment to build useful connected device prototypes. In short, hardware hacking has become accessible to the internet crowd on their weekends.

What’s more, crowdfunding sites like Kickstarter have made it possible to more easily market test and sell indie hardware. But producing is still hard. The existing manufacturing world isn’t geared towards producing in quantities of less than 10,000 units, and it’s not practical to take an Arduino, Raspberry Pi and 3D printed prototype and produce more than a handful of units. The space in-between — small batch manufacturing of around 500 units — is what’s needed to support hardware innovation at the scale of Kickstarter and Indiegogo.

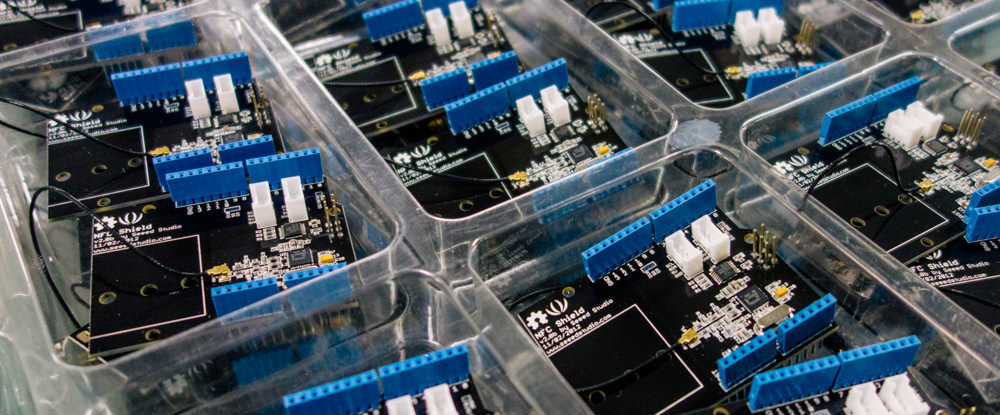

Seeed Studio hopes to fill this gap for indie hardware makers, through their community, open hardware component library and small batch production capabilities. Eric showed us one of their production facilities, which included a stock room of pre-assembled components from their open parts library. He explained how using such components lowers costs by allowing him to purchase in bulk on behalf of indie customers. Using the same standard components means that makers can benefit from the testing that’s been done across multiple projects.

He showed us hand-soldiering and assembly stations, desktop pick-and-place machines for making printed circuit boards and a MakerBot Replicator 2 for 3D-printing plastic parts. He showed us attractive packaging designs they’ve done and talked about how they partner with customers to share in the risk of design and production of small batch products. Having all of these capabilities under one roof — and across town from the same supply chain that supports things like the iPhone — gives makers the ability to do small batch manufacturing easily.

Eric seemed genuinely eager to work with small makers (they’ve worked with Ninja Blocks, Crazy Flie and RF Explorer) and is especially supportive of the open hardware movement. They’ve recently started changing their labels from “Made in China” to “Innovate with China” to better reflect the collaborative nature of indie hardware development. Exciting stuff.

![Innovate with China [Hack Things]](https://sloppy-joe-app.imgix.net/www/hackthings-logo.png)