LaMetric story: build a “look and feel” prototype before the crowdfunding campaign

Nazar Bilous is the co-founder Smart Atoms__,hardware startup that built LaMetric, and has founded several companies before, including digital agency Lemberg Solutions, Recordense.

Hardware is hard (no pun intended), especially building and delivering exactly what you’ve promised in your crowdfunding campaign. It’s important to avoid spending more time than expected after campaign when most of the team face a pressing deadline. Profound validation and a perfect prototype before hitting the Kickstarter campaign’s launch button will help you decrease the risks and make you more confident.

Most of our team used to work in a digital agency before forming Smart Atoms. We created several mobile apps and web products. Every day each of us was curious about the most important product numbers including app’s ranking, downloads, website stats. It took a lot of time getting them from different slow loading sites and we decided to solve it by having a simple device that saves our time, tracks the key numbers autonomously and shows them fresh for the whole team. A heated internal discussion expanded the idea to tracking not just the metrics but also the notifications and information like PayPal balance, amount of Facebook Fans, calendar events, twitter mentions, stock quotes, temperature and weather warnings, time and other. We came up with LaMetric, the smart ticker that tracks the most important information and gives people understanding what’s going on in their digital life and business saving their valuable time and making them more productive. We made the device standalone, very easy to set up with a smartphone, and customizable so that it outputs any important information run down with a combination of nice icon, scrolling text and sound. Thus, we integrated RSS, connection to IFTTT, and ability to output any info by simply sending a message to LaMetric’s email. For the most demanding users, we are going to implement API.

We started building LaMetric almost a year ago (like a great part of hardware startups out there). Arduino blocks helped us built MVP prototype and quickly proved the idea. Next, we created a concept what we intended to implement. We had to make sure that the outcome of the creation process will match our concept expectations. In the software world, you instantly slice your PSD and get exactly the same converted into an app or webpage. It’s much longer than that when it come to hardware.

LaMetric first prototype left, concept right

To be 100% sure that concept that you’ve created in a 3D software is feasible and will work in the real world, you need to check at least 3 things:

- Find the ideal size and weight.

- Think of a form factor that is both stylish and works.

- Mix in a particular technology like effect, lighting, material characteristic (depends on product idea).

Perfect size and weight

To help get the answer to what size works best, there is a very good and cheap technology – paper prototypes. We made several of those and selected one that works pretty good for a desk, wall and shop-front. For LaMetric, weight is not critical because it’s a stationary device. If you are developing a wearable gadget and mobility is important for your device, then you have to figure something out. At the end of the day, some devices end up just too heavy to wear.

Paper prototypes in different sizes

Getting the form factor right

In the course of several iterations, we moved from an ugly brick-like box to a rounded bar, after which most of the early adopters wanted to put LaMetric in the kitchen or living room. We now understand Apple’s passion for rounded rectangles, this works well in the 3D world, too. Initially, we created the casing using an average domestic 3D printer, but the quality was not good enough for us to get profound feedback, like “look and feel”. We discovered the Shapeways service that quickly transformed our model into high quality device parts.

![(Photo) The image shows two variations of a long, black, U-shaped object, possibly a handle or grip. One version appears smooth, while the other has etched symbols and a textured surface. Text: < | [] | > object | indoor | Two variations of the same object, close-up view, textured surface | macro | Colors: #000000 Note: The image appears to be a photograph of a physical object, showcasing its design and texture variations. It's not a logo, illustration, or other listed type.](https://sloppy-joe-app.imgix.net/blog_images/ii_s4vhoh92k.jpg)

One of LaMetric’s parts (home 3D printer left, Shapeways right)

Get particular technology

Nike+ Fuelband was a huge inspiration at LaMetric concept stage. Its amazing screen made the highest impact. We wanted to get the screen that looks like it is a part of the black casing when the device is switched off and clearly projects the screen across a large physical space with bright, sharp, square pixels. Most people that saw the 3D model doubted it’s even possible. Which motivated us even stronger to reach it.

We realised that existing LED matrix on the market will not help us to build the designed screen. We had to develop our own led screen combining different technologies. We made the second prototype that consisted of custom LED matrix, grid and overlay. Too bad the screen was not clear and looked blurry.

Prototype with a blurry screen

It was time for some heavyweight brainstorming. The team came up with different solutions how to get clear square pixels. We started experimenting with materials and their combinations. The third prototype was when we finally got it right..

Prototype with low screen’s brightness left, prototype with white color issue right

But that was not enough, the thickness of the material affects the screen’s brightness, so we started to seek the golden value of thickness. After several iterations, we got exactly what we wanted in terms of screen effect and brightness.

After some testing, we found yet one more surprise. The color and white leds had a different white color. To reach the same white color, we added additional white LEDs near the color LEDs and use them depending on what information is being shown. We redesigned the PCB and produced our fourth final prototype that proved that we can build what we had created in 3D MAX a while ago. In the course of development, we have made some more improvements to LaMetric: added a speaker and touch buttons, made it longer (one retail chain wanted to show to passers-by millions of their Facebook Fans).

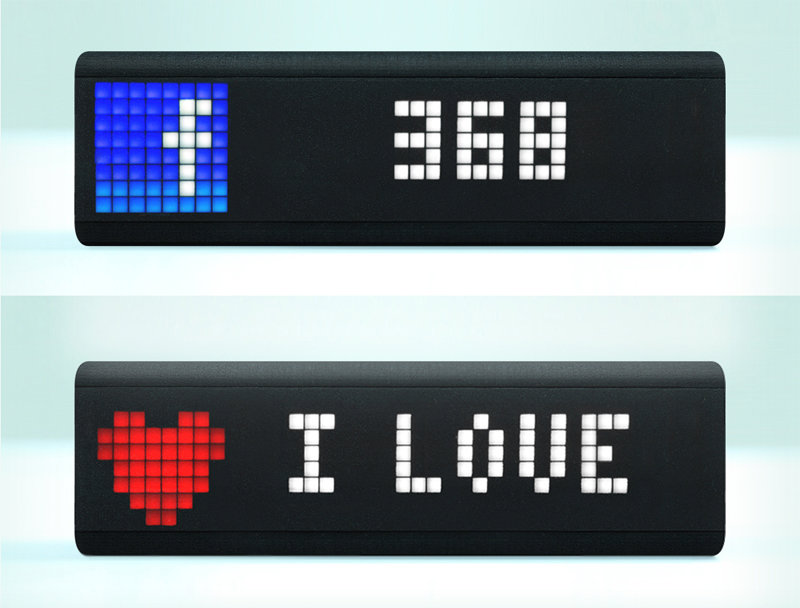

The Final LaMetric prototype

We’ve gone full cycle and now all in the team clearly understand that creating real things is a much longer process than building an app or website from PSD.

The process is very interesting and exciting; it’s like gold-digging: while experimenting with solutions, you may discover a new technology, add improvements, make the impossible possible, and what’s most important, make sure that your gadget will match all expectations before launching a Kickstarter campaign.

![LaMetric story: build a “look and feel” prototype before the crowdfunding campaign [Hack Things]](https://sloppy-joe-app.imgix.net/www/hackthings-logo.png)