Poppy in production

I’m in China visiting our factory as we begin production of Poppy, our inexpensive and battery-free gadget that turns your iPhone into a 3D video recording and playback device. We have been working on this for almost a year now, and raised roughly $200K on Kickstarter this past summer, but yesterday was a huge milestone on the journey: we made the first injection molded plastic Poppy, called the “first shot”.

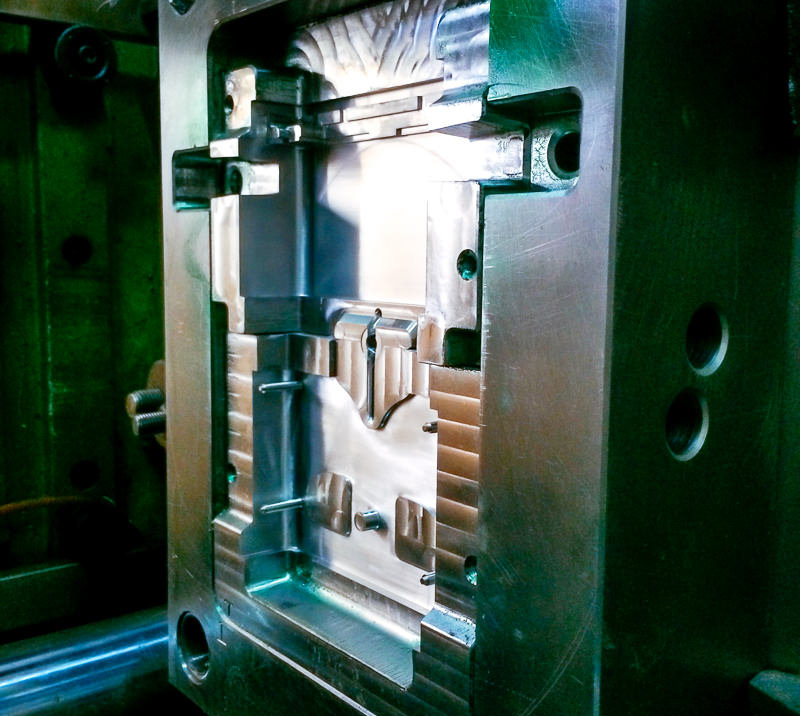

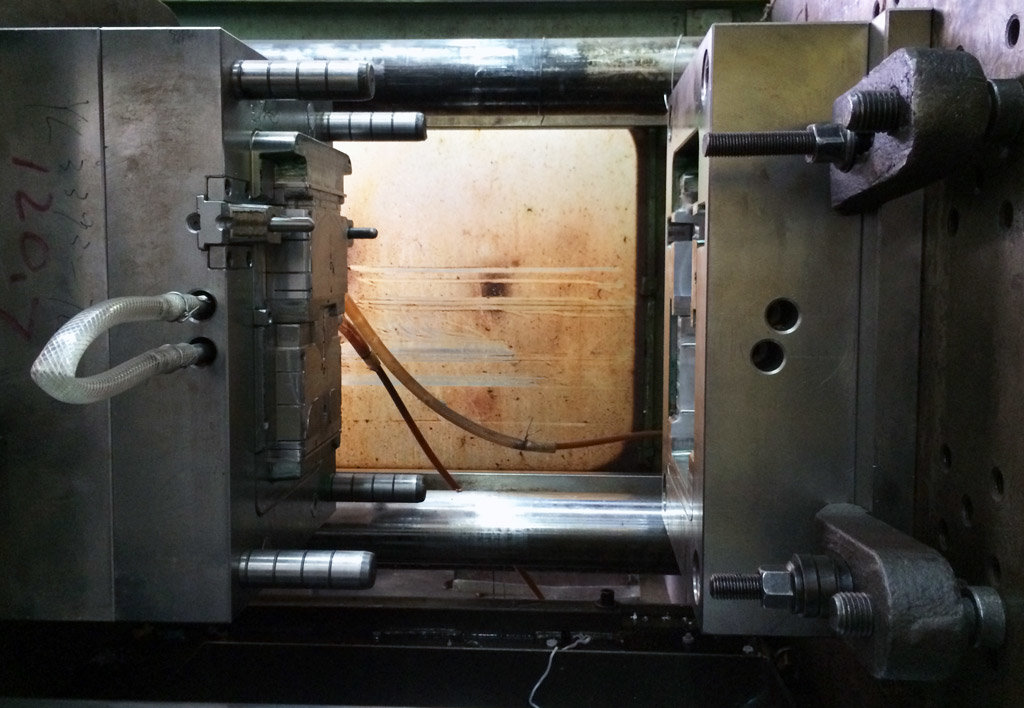

Injection molding is a kind of magic. The molds themselves are huge, heavy blocks of steel. The machines look like something out of steam punk science fiction. A bulbous hopper of plastic pellets is suspended over a heating element. Molten plastic is shot into the mold. The plastic cools, the jaws of the mold open, and a robotic arm plucks out the newly minted part. Total elapsed time per part: less than 20 seconds.

We’ve been watching this process move from sketches to cardboard prototypes, to 3D printed models, through iterations of machined prototypes and now molded parts. This latest step is special: it’s the move from one-off to mass production. I’m so excited to be here, and really enjoying seeing it happen in person.

So how does Poppy look? Really good! That’s not to say we’re done, far from it. As expected, these first units have flaws. The rotation is a little loose. The logo is printed upside down. The tripod screw mount sticks out slightly. The cartridge for the iPhone 4 has a nubbin of plastic that keeps it from being inserted properly. The molds haven’t been textured or polished. We’re working through dozens of issues. But (so far at least, knock on wood) we haven’t seen anything that can’t be fixed or tuned in the normal course of preparing for the full production run.

We did come close at one point, though. When I first looked through the viewfinder the image was slightly blurry and we all had a moment of panic thinking that the lenses might be flawed — finding a new supplier at this stage would push back our ship date. But it turns out the lenses had just been loaded in backwards. A very good thing to catch now before thousands of these things were assembled incorrectly, and a simple fix!

We’re packing these first few Poppys to ship to our pre-production Kickstarter backers. They’ll see it in all its imperfect glory, but also get one of the finished product when it’s ready. We’re also beginning the refinements necessary so we can produce 5000 more Poppys in the next few weeks, and finalizing our logistics and fulfillment plans. We’re getting a healthy dose of why hardware is “hard” — more on that later. Here are some behind the scenes photos as we round the bend into the home stretch.

![Poppy in production [Hack Things]](https://sloppy-joe-app.imgix.net/www/hackthings-logo.png)