The innovation advantage of being in China

In software the key to innovation is rapid iteration. That’s much more challenging with hardware, and working remotely with a Chinese manufacturer has been excruciating at times. You discuss a change, then wait days or weeks to see the results. Skype and email can only go so far, and the language and cultural barriers are significant. Shipping prototypes and samples back and forth is expensive — for our little product that means hundreds of dollars each time, each way.

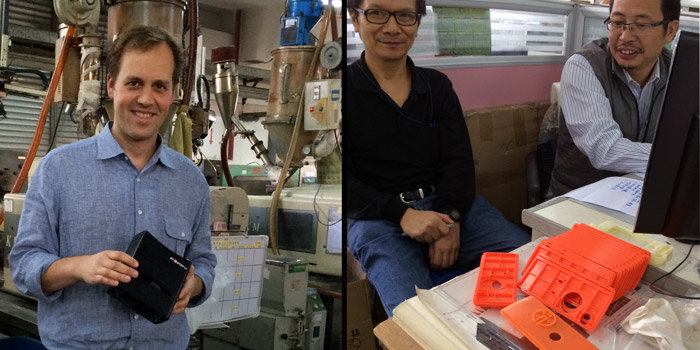

But being here in person is completely different. The mechanical engineers are in the next room. The factory floor is just across the parking lot. The bag supplier, the neck strap maker, the printer, the box maker — all of these suppliers are located within minutes of the factory. We can make decisions, iterate, refine, test, and get fresh production-ready samples all in hours or days instead of weeks. And language barriers are greatly reduced face-to-face, especially when you can both touch the same physical product you are working on.

In short, the pace of progress on the ground is much closer to what I’m used to in software. This suggests that for innovation to move faster we need to shorten the distance, in every sense, between inventors and the factory.

One answer is to just spend a ton of time in China. We’ve met a lot of hardware startups that relocated to China for months, some that moved here permanently. Being here the advantages are very clear. But it’s also challenging. It’s expensive and time-consuming to get here, and inconvenient or even daunting to be so far from home.

The alternative is to bring more production capabilities closer to the innovators themselves. This is a little different than the classic, “bring factory jobs back to America” argument. We need more manufacturing at home because rapid iteration is easiest when the designer and the producer are in the same room, and it’s not practical for everyone to hop on a plane to China.

As Marc Andreessen noted, “It’s called hardware for a reason — it is hard”. We should be doing everything possible to make it easier. Sitting here in China, hardware development is much, much easier for me to do than it was last week in California.

![The innovation advantage of being in China [Hack Things]](https://sloppy-joe-app.imgix.net/www/hackthings-logo.png)